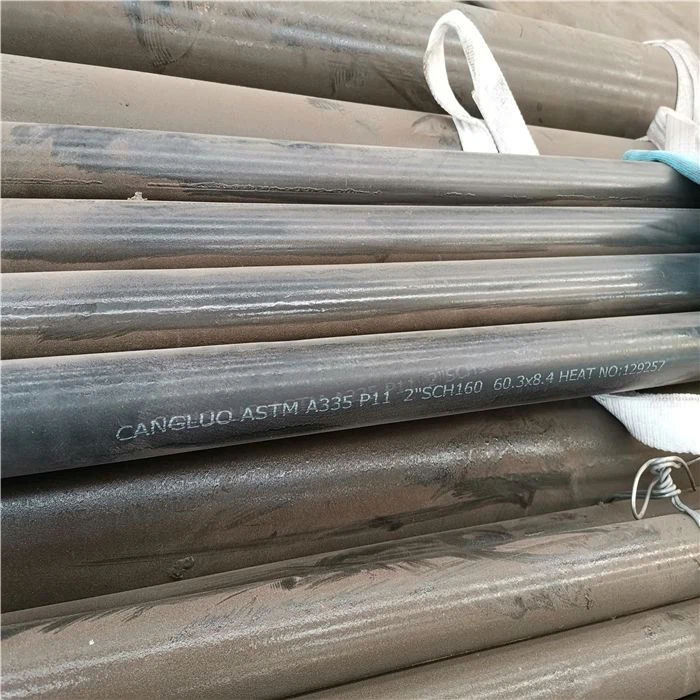

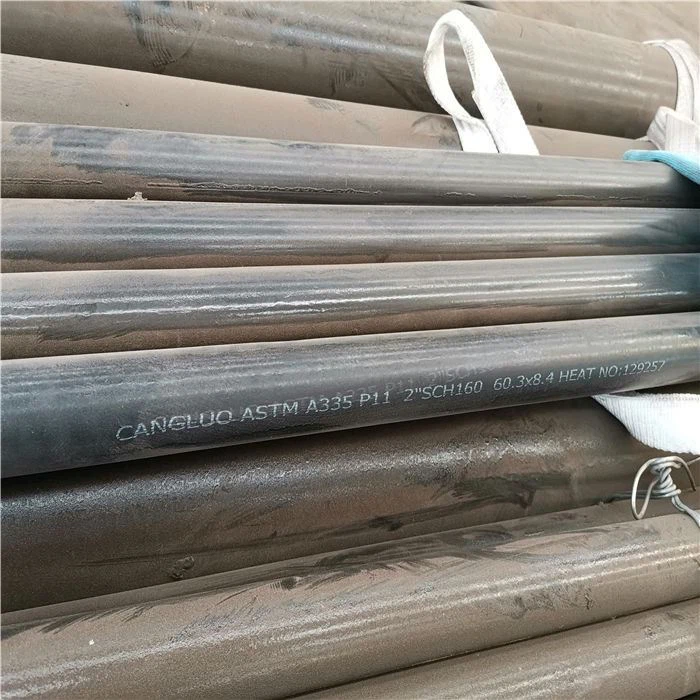

ASTM A335 P11 alloy boiler Tube

ASTM A335 P11 Pipe is used for high temperature services The pipes are also known as 1 25Cr-0 5Mo pipes because

Product Introduction

ASTM A335 P11 Pipe is used for high temperature services. The pipes are also known as 1.25Cr-0.5Mo pipes because of the chromium and molybdenum content in the material.

ASTM A335 Gr P11 Pipe has similar strength as other A335 specification grades. The minimum yield strength is 205MPa and the minimum tensile strength 415MPa. The material can be heat treated through isothermal annealing or normalizing and tempering at temperature above 650 degrees Celsius for added strength. The ASTM A335 P11 Alloy Steel Pipe is prone to cold cracking. So the material has to be preheated for welding and post weld heat treated at a temperature range of 300 degrees to 350 degrees Celsius. The pipes have to be cooled down to room temperatures before being used in applications.

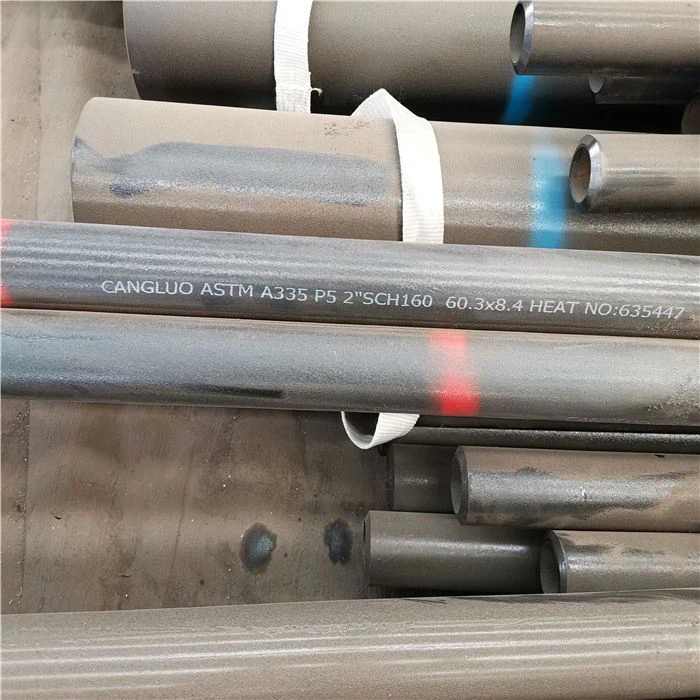

As one of the leading Sa335 P11 Pipe Suppliers we supply the products in large quantities and in various dimensions. The wall thicknesses of the pipes range from 2mm to 44mm and the outer dimensions range from 19.05mm to 610mm. and we also P5, P9, P22, P91 steel grade pipes and fittings.

P11 Alloy Steel Pipe Chemical Composition

Alloy Steel A335 P11 Pipes Chemical Composition

| Alloy Steel P11 | C | Cr | Mn | Mo | P | S | Si |

| 0.05 – 0.15 | 1.00 – 1.50 | 0.30 – 0.60 | 0.44 – 0.65 | 0.025 max | 0.025 max | 0.50 – 1.00 |

Alloy Steel Gr.P11 Pipe Mechanical Properties

Alloy Steel P11 UNS K11597 Pipe Mechanical Properties

| Tensile Strength, MPa | Yield Strength, MPa | Elongation |

| 415 min | 205 min | 30 min |

ASTM A335 Pipe Material Heat Treatment Requirements

| Grade | Heat Treatment Type | Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering Temperature Range F [C] |

|---|---|---|---|

| P5 (b,c) | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| Subcritical Anneal (P5c only) | ***** | 1325 – 1375 [715 – 745] | |

| P9 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P11 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1200 [650] | |

| P22 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P91 | Normalize and Temper | 1900-1975 [1040 – 1080] | 1350-1470 [730 – 800] |

| Quench and Temper | 1900-1975 [1040 – 1080] | 1350-1470 [730 – 800] |

SA335 Pipe Tensile Requirements

| Seamless | |||||

|---|---|---|---|---|---|

| P-5 | P-9 | P-11 | P-22 | P-91 | |

| Tensile Strength, min., psi | |||||

| ksi | 60 | 60 | 60 | 60 | 85 |

| MPa | 415 | 415 | 415 | 415 | 585 |

| Yield Strength, min., psi | |||||

| ksi | 30 | 30 | 30 | 30 | 60 |

| MPa | 205 | 205 | 205 | 205 | 415 |

| ASTM A335 P11 Pipe Types | Out diameter | Wall thickness | Length |

|---|---|---|---|

| ASTM A335 P5, P9, P11, P91 Seamless Pipe (Custom Sizes) | 1/2" NB - 24" NB | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Custom |

My company hot sale steel pipe

Boiler tubes,( 20G. 12Cr1MoVG, ASTM A335 P5, P9, P11),

ASTM A333 GR.6 seamless pipes, ( 1” to 24” sch40, sch80, sch160),

TP304/304L, TP316/TP316L, stainless steel pipes, (1” to 48” sch10, sch20, sch40, sch80),

You Might Also Like

-

large diameter Seamless Line Pipes API 5L GR.B 1016x25.4 mm 6 m length

-

St37 Seamless Tube 88.9mm Diameter

-

Seamless Steel Pipe ASTM A106 B NACE MR 0175 12IN SCH160

-

Seamless Line Pipe API 5L GR.B 24INCH SCH40 12M Length

-

Seamless Pipe 2inch Idimeter XXS 6 M LENGTH Export

-

Seamless Pipe ASTM A106 C 10IN Diameter XS 12M Length

Send Inquiry