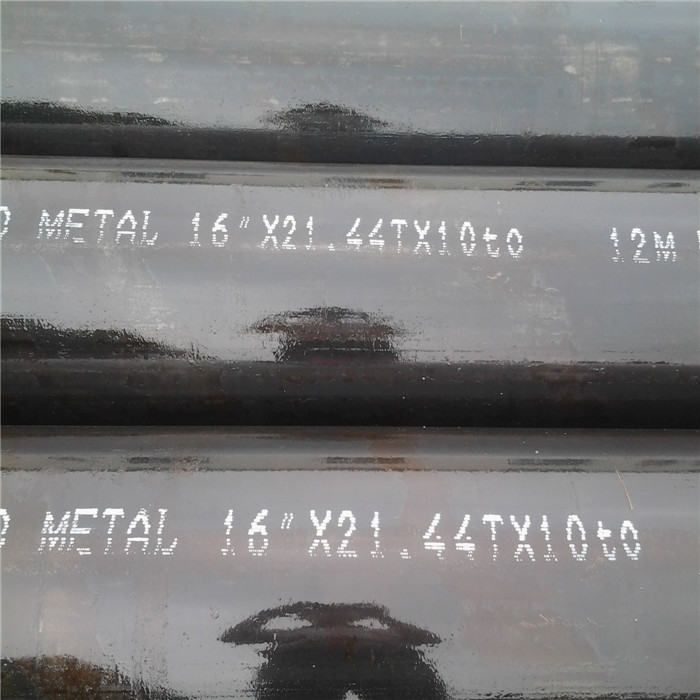

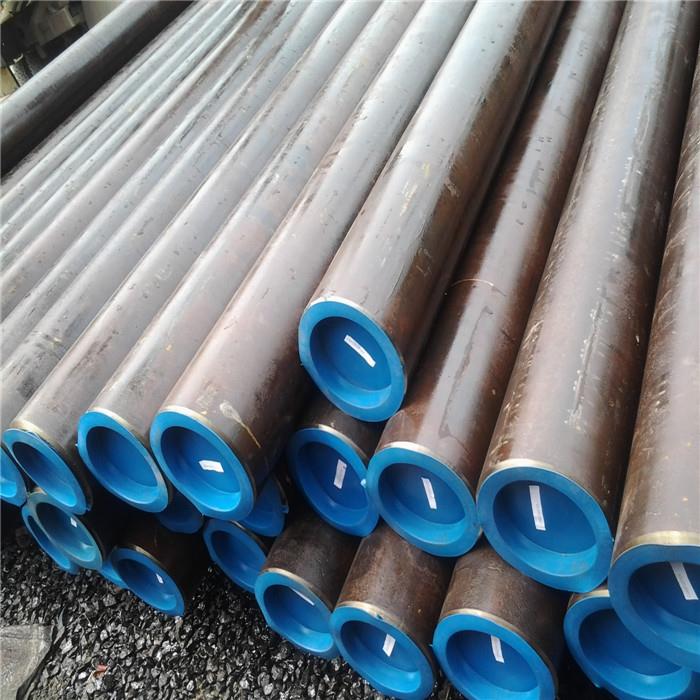

Seamless Pipe API 5L X60 PSL2 3PE coated 16" SCH80 12M Length

API 5L PIPES - API 5L SEAMLESS LINE PIPESThisAPI 5L SpecificationCovers Seamless and Welded Steel Line Pipe It

Product Introduction

API 5L PIPES - API 5L SEAMLESS LINE PIPES

This API 5L Specification Covers Seamless and Welded Steel Line Pipe. It includes standard-weight and Extra-Strong threaded Line Pipe. It includes standard-weight and extra-strong threaded line pipe; and standard-weight plain-end, regular-weight plain-end, special plain-end, extra-strong plain-end, special plain-end, extra-strong plain-end pipe; as as well as bell and spigot and through-the-flow line(TFL) pipe.

The purpose of this specification is to provide standards for pipe suitable for use in conveying gas, water, and oil in both the oil and natural gas industries

Grades covered by this specification are A25 ,A ,B (and the following "X" Grades), X42, X46, X52, X56, X60, X65, X70, X80. The two digit number following the "X" indicates the Minimum Yield Strength (in 000's psi) of pipe produced to this grade.

We can supply full range of API 5L Seamless Pipes in PSL-1 & PSL-2 line pipe.

We carry a full inventory of API 5L Pipe Carbon Steel Pipe products in a variety of sizes to meet the structural piping requirements for applications the water, petroleum, oil & gas and other industries. API 5L Seamless Pipe Carbon Steel Pipe can be Structural in Nature or used in Fluid, Gas, Oil Transmission.

The grade indicates the testing methods required for a given application. It is critical that structural grades of Carbon Steel Pipe not be used for Pressure or Fluid applications.

API 5L Line Pipe can be either seamless or welded. Applications for API 5L include, but are not limited to: petroleum, petrochemical, natural gas industries, and waterworks.

My company is a pipe manufacturer and pipe distributor in Middle East, Far East and Africa Region that provides API 5L line pipe from 1/2" to 64" in diameter, in grades X42, X46, X52, X60, X65, & X70.

Chemical Composition For PSL 2 Pipe With T ≤ 0.984”

| Steel Grade | Mass fraction, % based on heat and product analyses | Carbon Equiv a | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | V | Nb | Ti | Other | CE IIW | CE Pcm | |||||||||||

| max b | max | max b | max | max | max | max | max | max | max | ||||||||||||

| Seamless and Welded Pipe | |||||||||||||||||||||

| BR | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.043 | 0.25 | ||||||||||

| X42R | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.043 | 0.25 | ||||||||||

| BN | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.043 | 0.25 | ||||||||||

| X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.043 | 0.25 | ||||||||||

| X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | d,e,l | 0.043 | 0.25 | ||||||||||

| X52N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | d,e,l | 0.043 | 0.25 | ||||||||||

| X56N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.10f | 0.05 | 0.04 | d,e,l | 0.043 | 0.25 | ||||||||||

| X60N | 0.24f | 0.45f | 1.40f | 0.025 | 0.015 | 0.10f | 0.05f | 0.04f | g,h,l | As agreed | |||||||||||

| BQ | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.043 | 0.25 | ||||||||||

| X42Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.043 | 0.25 | ||||||||||

| X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.043 | 0.25 | ||||||||||

| X52Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.043 | 0.25 | ||||||||||

| X56Q | 0.18 | 0.45f | 1.5 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | e,l | 0.043 | 0.25 | ||||||||||

| X60Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.043 | 0.25 | ||||||||||

| X65Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.043 | 0.25 | ||||||||||

| X70Q | 0.18f | 0.45f | 1.80f | 0.025 | 0.015 | g | g | g | h,l | 0.043 | 0.25 | ||||||||||

| X80Q | 0.18f | 0.45f | 1.90f | 0.025 | 0.015 | g | g | g | i,j | As agreed | |||||||||||

| X90Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | As agreed | |||||||||||

| X100Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | As agreed | |||||||||||

| Welded Pipe | |||||||||||||||||||||

| BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.043 | 0.25 | ||||||||||

| X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.043 | 0.25 | ||||||||||

| X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.043 | 0.25 | ||||||||||

| X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.043 | 0.25 | ||||||||||

| X56M | 0.22 | 0.45f | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.043 | 0.25 | ||||||||||

| X60M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.043 | 0.25 | ||||||||||

| X65M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.043 | 0.25 | ||||||||||

| X70M | 0.12f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.043 | 0.25 | ||||||||||

| X80M | 0.12f | 0.45f | 1.85f | 0.025 | 0.015 | g | g | g | i,j | .043f | 0.25 | ||||||||||

| X90M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | i,j | – | 0.25 | ||||||||||

| X100M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | i,j | – | 0.25 | ||||||||||

| a. SMLS t>0.787”, CE limits shall be as agreed. The CEIIW limits applied fi C > 0.12% and the CEPcm limits apply if C ≤ 0.12%, b. For each reduction of 0.01% below the specified max. concentration for carbon, and increase of 0.05% above the specified max. concentration for Mn is permissible, up to a max. of 1.65% for grades ≥ B, but ≤ = X52; up to a max. of 1.75% for grades > X52, but < X70; and up to a maximum of 2.00% for X70., c. Unless otherwise agreed Nb = V ≤ 0.06%, d. Nb = V = Ti ≤ 0.15%, e. Unless otherwise agreed, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% and Mo ≤ 0.15%, f. Unless otherwise agreed, g. Unless otherwise agreed, Nb + V + Ti ≤ 0.15%, h. Unless otherwise agreed, Cu ≤ 0.50% Ni ≤ 0.50% Cr ≤ 0.50% and MO ≤ 0.50%, i. Unless otherwise agreed, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.50% and MO ≤ 0.50%, j. B ≤ 0.004%, k. Unless otherwise agreed, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.55% and MO ≤ 0.80%, l. For all PSL 2 pipe grades except those grades with footnotes j noted, the following applies. Unless otherwise agreed no intentional addition of B is permitted and residual B ≤ 0.001% . |

|||||||||||||||||||||

Mechanical Properties

| Pipe Grade | Tensile Properties – Pipe Body of SMLS and Welded Pipes PSL 2 | Seam of Welded Pipe | |||||

|---|---|---|---|---|---|---|---|

| Yield Strength a | Tensile Strength a | Ratio a,c | Elongation | Tensile Strength d | |||

| Rt0,5 PSI Min | Rm PSI Min | R10,5IRm | (in 2in) | Rm (psi) | |||

| Af % | |||||||

| Minimum | Maximum | Minimum | Maximum | Maximum | Minimum | Minimum | |

| BR, BN,BQ,BM | 35,500 | 65,300 | 60,200 | 95,000 | 0.93 | f | 60,200 |

| X42,X42R,X2Q,X42M | 42,100 | 71,800 | 60,200 | 95,000 | 0.93 | f | 60,200 |

| X46N,X46Q,X46M | 46,400 | 76,100 | 63,100 | 95,000 | 0.93 | f | 63,100 |

| X52N,X52Q,X52M | 52,200 | 76,900 | 66,700 | 110,200 | 0.93 | f | 66,700 |

| X56N,X56Q,X56M | 56,600 | 79,000 | 71,100 | 110,200 | 0.93 | f | 71,100 |

| X60N,X60Q,S60M | 60,200 | 81,900 | 75,400 | 110,200 | 0.93 | f | 75,400 |

| X65Q,X65M | 65,300 | 87,000 | 77,600 | 110,200 | 0.93 | f | 76,600 |

| X70Q,X65M | 70,300 | 92,100 | 82,700 | 110,200 | 0.93 | f | 82,700 |

| X80Q,X80M | 80,.500 | 102,300 | 90,600 | 119,700 | 0.93 | f | 90,600 |

| a. For intermediate grade, refer to the full API5L specification. | |||||||

| b. for grades > X90 refer to the full API5L specification. | |||||||

| c. This limit applies for pies with D> 12.750 in | |||||||

| d. For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body using foot a. | |||||||

| e. for pipe requiring longitudinal testing, the maximum yield strength shall be ≤ 71,800 psi | |||||||

| f. The specified minimum elongation, Af, expressed in percent and rounded to the nearest percent, shall be determined using the following equation: | |||||||

|

|||||||

| Where C is 1 940 for calculation using Si units and 625 000 for calculation using USC units | |||||||

| Axc is the applicable tensile test piece cross-sectional area, expressed in square millimeters (square inches) , as follows | |||||||

| – For circular cross-section test pieces, 130mm2 (0.20 in2) for 12.7 mm (0.500 in) and 8.9 mm (.350 in) diameter test pieces; and 65 mm2 (0.10 in2) for 6.4 mm (0.250in) diameter test pieces. | |||||||

| – For full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.10in2) | |||||||

| – For strip test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.10in2) | |||||||

| U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch | |||||||

| g. Lower values fo R10,5IRm may be specified by agreement | |||||||

| h. for grades > x90 refer to the full API5L specification. | |||||||

Hydrostatic Test

Pipe to withstand a hydrostatic test without leakage through the weld seam or the pipe body. Jointers need not be hydrostatic tested provide the pipe sections used were successfully tested.

Bend Test

No cracks shall occur in any portion of the test piece and no opening of the weld shall occur.

Flattening Test

Acceptance criteria for flattening test shall be:

-

EW pipes D<12.750 in:

-

X60 with T 500in. There shall be no opening of the weld before the distance between the plates is less than 66% of the original outside diameter. For all grades and wall, 50%.

-

For pipe with a D/t > 10, there shall be no opening of the weld before the distance between the plates is less than 30% of the original outside diameter.

-

For other sizes refer to the full API 5L specification.

CVN Impact Test For PSL2

Many PSL2 pipe sizes and grades require CVN. Seamless pipe is to be tested in the body. Welded pipe is to be tested in the body, pipe weld and heat-affected zone. Refer to the full API 5L specification for the chart of sizes and grades and required absorbed energy values.

My company hot sale seamless steel line pipes:

ASTM A106 B seamless pipes, API 5L GR.B seamless steel pipes(1” to 24” sch40, sch80),

API 5L X52, X65, X70 PSL2 seamless line pipe (2” to 24” sch40, sch80, sch160),

You Might Also Like

-

large diameter Seamless Line Pipes API 5L GR.B 1016x25.4 mm 6 m length

-

St37 Seamless Tube 88.9mm Diameter

-

Seamless Steel Pipe ASTM A106 B NACE MR 0175 12IN SCH160

-

Seamless Line Pipe API 5L GR.B 24INCH SCH40 12M Length

-

Seamless Pipe 2inch Idimeter XXS 6 M LENGTH Export

-

Seamless Pipe ASTM A106 C 10IN Diameter XS 12M Length

Send Inquiry