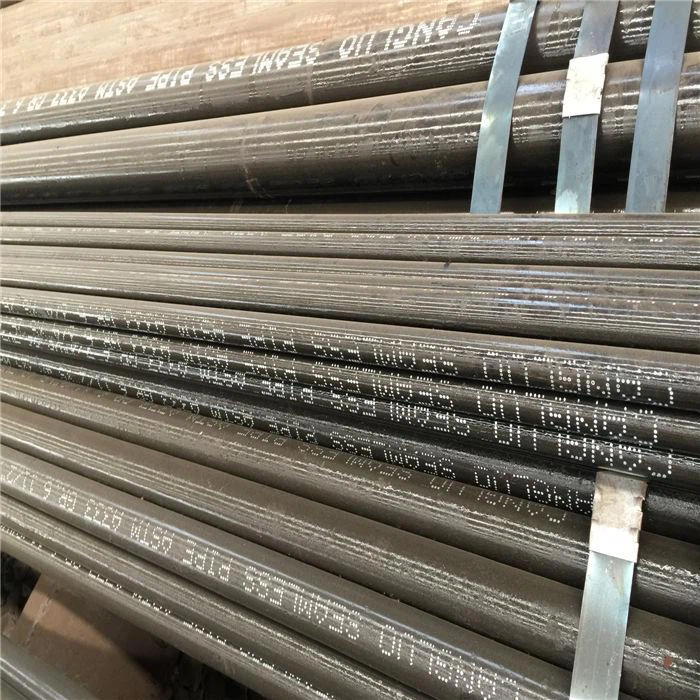

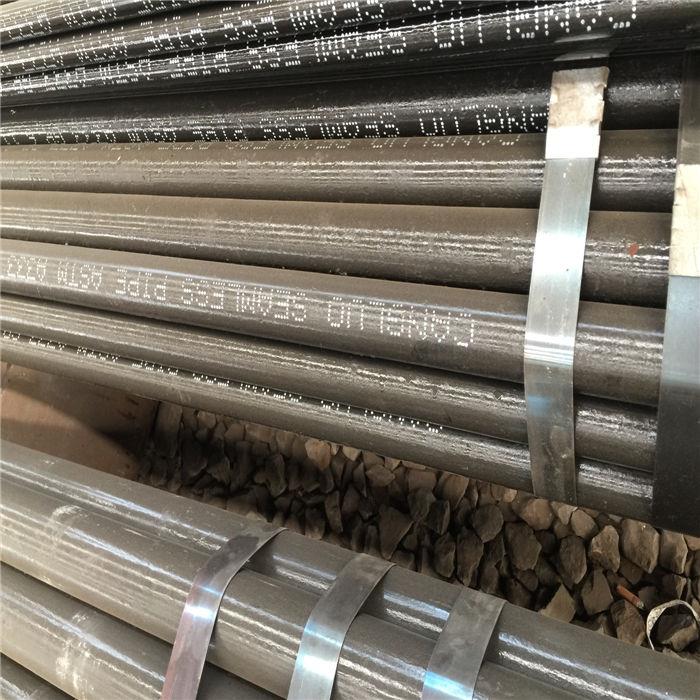

Seamless Tube For Low Temperature Environment

ASTM A333 Grade 6, Seamless Steel Pipe for Low-Temperature ServiceASTM A333Standardcovers seamless and welded steel

Product Introduction

ASTM A333 Grade 6, Seamless Steel Pipe for Low-Temperature Service

ASTM A333 Standard covers seamless and welded steel pipe for low temperature service. The Grade 6 steel involved is similar to AISI 4032 low alloy steel. ASTM A333 Grade 6 pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation.

Available Size:

Outer Dimensions: 19.05mm – 457mm

Wall Thickness:2.0mm – 30 mm

Length: 6-24m

Steel grade: ASTM A333 Grade 6

Packing: Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

Inspection and Test: Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength,Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test,No-destructive Test, Hydrostatic Test.

Surface treatment: Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting.

Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested.

Packing: Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

Chemical Requirement Composition(%)

| Composition | ASTM A333 Grade 6 |

| Carbon, max | 0.30 |

| Manganese | 0.29–1.06 |

| Phosphorus, max | 0.025 |

| Sulfur, max | 0.025 |

A For each reduction of 0.01% carbon below 0.30%, an increase of 0.05% manganese above 1.06% would be permitted to a maximum of 1.35% manganese.

TENSILE REQUIREMENTS

| Data |

ASTM A333 Grade 6 |

| Tensile strength, min, psi (MPa) |

60 000 (415) |

| Yield strength, min, psi (MPa) |

35 000 (240) |

Impact Temperature

Minimum Impact Test Temperature -45 C(-50 F)

Impact Requirements

| Size | Minimum Average Notched Bar Impact Value of Each Set of Three Specimens | Minimum Notched Bar Impact Value of One Specimen Only of a Set | ||

| Size of Specimen, mm |

ft-lbf |

J |

ft-lbf |

J |

| 10 by 10 |

13 |

18 |

10 |

14 |

| 10 by 7.5 |

10 |

14 |

8 |

11 |

| 10 by 6.67 |

9 |

12 |

7 |

9 |

| 10 by 5 |

7 |

9 |

5 |

7 |

| 10 by 3.33 |

5 |

7 |

3 |

4 |

| 10 by 2.5 |

4 |

5 |

3 |

4 |

Straight line interpolation for intermediate values is permitted.

Machinability

Machinability is good, similar to law alloy 4032 steel.

Forming

The product comes in piping form but may be formed readily by conventional methods.

Heat Treatment

Product is supplied in the normalized, 1500 f and air cooled, condition. It may be quenched and tempered by heating to 1475 F, quench in circulating water and then temper by re-heating to 1100 F and rapid air cooling.

My company hot sale alloy seamless tubes

Boiler tubes,( 20G. 12Cr1MoVG, ASTM A335 P5, P9, P11),

ASTM A333 GR.6 seamless pipes, ( 1” to 24” sch40, sch80, sch160),

You Might Also Like

-

large diameter Seamless Line Pipes API 5L GR.B 1016x25.4 mm 6 m length

-

St37 Seamless Tube 88.9mm Diameter

-

Seamless Steel Pipe ASTM A106 B NACE MR 0175 12IN SCH160

-

Seamless Line Pipe API 5L GR.B 24INCH SCH40 12M Length

-

Seamless Pipe 2inch Idimeter XXS 6 M LENGTH Export

-

Seamless Pipe ASTM A106 C 10IN Diameter XS 12M Length

Send Inquiry