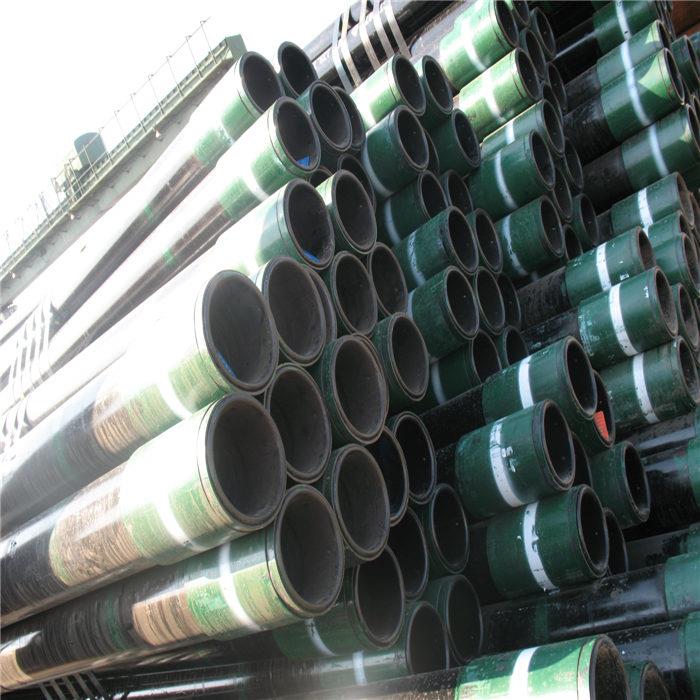

Casing 20IN, 106.5 Ppf, K-55 , R-3, BTC

What is API 5CT Casing and Tubing?OCTG: Oil country tubular goods is the classification used for a variety of d

Product Introduction

What is API 5CT Casing and Tubing?

OCTG: Oil country tubular goods is the classification used for a variety of downhole products

API 5CT Casing and Tubing serves to transport both crude oil and natural gas from oil and gas layer to the surface pipeline after drilling is completed. It is able to bear the pressure produced by the exploitation process. After the outer surface is coated with a protective layer, the tubing is marked in accordance with the API 5CT standard and strapped with metal belt.

Our oilfield tubing & API 5CT Casing and Tubing can be widely applicable to petroleum, construction, shipbuilding, smelting, aviation, electric power, food, paper, chemical industry, medical equipment, boilers, heat exchangers, metallurgy and so on.

This oilfield tubing can be classified as NUE type and EUE type. The specifications include 1.9in(48.3mm), 2 3/8in(60.3mm), 2 7/8in(73.03mm), 3 1/2in(88.9mm), 4in(101.6mm), 4 1/2in(114.3mm) etc. The depth of our product for descending the well is basically identical to that of oil casing pipe. Both mechanical property and sealing performance of this tubing are also required to correspond with the oil casing pipe. Petroleum Tubing main steel grade includes J55, N80, C90, P110 and some others. for more details check below Casing And Tubing Tables, Casing Grade Table, & Casing Data Tables.

API 5CT K55 Casing:

K55 Casing is placed downhole to provide structural integrity to the wellbore and must withstand external-collapse pressure from rock formations and internal-yield pressure from fluid and gas. It must also hold its own deadweight and withstand the torque and transaxial pressure placed on it while running downhole.

API 5CT K55 Tubing:

K55 Tubing is placed within the casing. It is used to transport oil and gas from the source rock to the wellhead.

API 5CT K55 Casing Tubing Chemical Composition, mass fraction (%)

| Group | Grade | Type | C | Mn | Mo | Cr | Ni max. | Cu max. | P max. | S max. | Si max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | min. | max. | min. | max. | min. | max. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

|

1 |

H40 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

- |

|

J55 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

- |

|

|

K55 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

- |

|

|

N80 |

1 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

- |

|

|

N80 |

Q |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

- |

|

|

R95 |

- |

- |

0.45 c |

- |

1.9 |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

0.45 |

|

|

2 |

M65 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

- |

|

L80 |

1 |

- |

0.43 a |

- |

1.9 |

- |

- |

- |

- |

0.25 |

0.35 |

0.03 |

0.03 |

0.45 |

|

|

L80 |

9Cr |

- |

0.15 |

0.3 |

0.6 |

0.9 |

1.1 |

8 |

10 |

0.5 |

0.25 |

0.02 |

0.01 |

1 |

|

|

L80 |

13Cr |

0.15 |

0.22 |

0.25 |

1 |

- |

- |

12 |

14 |

0.5 |

0.25 |

0.02 |

0.01 |

1 |

|

|

C90 |

1 |

- |

0.35 |

- |

1.2 |

0.25 b |

0.85 |

- |

1.5 |

0.99 |

- |

0.02 |

0.01 |

- |

|

|

T95 |

1 |

- |

0.35 |

- |

1.2 |

0.25 d |

0.85 |

0.4 |

1.5 |

0.99 |

- |

0.02 |

0.01 |

- |

|

|

C110 |

- |

- |

0.35 |

- |

1.2 |

0.25 |

1 |

0.4 |

1.5 |

0.99 |

- |

0.02 |

0.005 |

- |

|

|

3 |

P110 |

e |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 e |

0.030 e |

- |

|

4 |

Q125 |

1 |

- |

0.35 |

1.35 |

- |

0.85 |

- |

1.5 |

0.99 |

- |

0.02 |

0.01 |

- |

|

| a The carbon content for L80 may be increased up to 0.50 % maximum if the product is oil-quenched. b The molybdenum content for Grade C90 Type 1 has no minimum tolerance if the wall thickness is less than 17.78 mm. c The carbon content for R95 may be increased up to 0.55 % maximum if the product is oil-quenched. d The molybdenum content for T95 Type 1 may be decreased to 0.15 % minimum if the wall thickness is less than 17.78 mm. e For EW Grade P110, the phosphorus content shall be 0.020 % maximum and the sulfur content 0.010 % maximum. NL = no limit. Elements shown shall be reported in product analysis. |

|||||||||||||||

API 5CT K55 Casing Tubing Mechanical Properties

| Standard | Type | Tensile Strength MPa |

Yield Strength MPa |

Hardness Max. |

|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

API 5CT K55 Casing Tubing Tensile and hardness requirements

| Group | Grade | Type | Total elongation under load % | Yield strength MPa | Tensile strength min. MPa | Hardness a max. | Specified wall thickness mm | Allowable hardness variation b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max . | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 |

H40 |

- |

0.5 |

276 |

552 |

414 |

- |

- |

- |

- |

|

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

- |

- |

|

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

- |

- |

|

|

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

- |

- |

|

|

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

- |

- |

|

|

R95 |

- |

0.5 |

655 |

758 |

724 |

- |

- |

- |

- |

|

| 2 |

M65 |

- |

0.5 |

448 |

586 |

586 |

22 |

235 |

- |

- |

|

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

|

|

L80 |

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

|

|

L80 |

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

|

|

C90 |

1 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

≤ 12.70 12.71 to 19.04 19.05 to 25.39 ≥ 25.40 |

3.0 4.0 5.0 6.0 |

|

|

T95 |

1 |

0.5 |

655 |

758 |

724 |

25.4 |

255 |

≤ 12.70 12.71 to 19.04 19.05 to 25.39 ≥ 25.40 |

3.0 4.0 5.0 6.0 |

|

|

C110 |

- |

0.7 |

758 |

828 |

793 |

30 |

286 |

≤ 12.70 12.71 to 19.04 19.05 to 25.39. ≥ 25.40 |

3.0 4.0 5.0 6.0 |

|

| 3 |

P110 |

- |

0.6 |

758 |

965 |

862 |

- |

- |

- |

- |

| 4 |

Q125 |

1 |

0.65 |

862 |

1034 |

931 |

b |

- |

≤ 12.70 12.71 to 19.04 ≥ 19.05 |

3.0 4.0 5.0 |

| a In case of dispute, laboratory Rockwell C hardness testing shall be used as the referee method. b No hardness limits are specified, but the maximum variation is restricted in accordance with 7.8 and 7.9 of API Spec. 5CT. |

||||||||||

API 5CT K55 Casing Tubing Steel color code

| Name | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Casing | a bright green band | two bright green bands | a bright red band | a bright red band + a green band | a red band + a brown band | a bright white band |

| Coupling | entire green coupling + a white band | entire green coupling | entire red coupling | entire red coupling + a green band | entire red coupling + a brown band | entire white coupling |

Galaxy Company Hot Sale Steel Pipe Products:

OCTG, casing, tubing, seamless steel pipe, line pipe, boiler tube, ASTM A333 pipe, ASTM A335 alloy pipes, Mechanical pipe, API 5L pipe,

You Might Also Like

-

large diameter Seamless Line Pipes API 5L GR.B 1016x25.4 mm 6 m length

-

St37 Seamless Tube 88.9mm Diameter

-

Seamless Steel Pipe ASTM A106 B NACE MR 0175 12IN SCH160

-

Seamless Line Pipe API 5L GR.B 24INCH SCH40 12M Length

-

Seamless Pipe 2inch Idimeter XXS 6 M LENGTH Export

-

Seamless Pipe ASTM A106 C 10IN Diameter XS 12M Length

Send Inquiry