Effect Of Nitrogen On Steel Pipe Performance

Under general conditions, the main damage of nitrogen is as follows:

(1) Due to the precipitation of Fe4N, the timeliness of steel;

(2) reduce the cold working properties of steel;

(3) Embrittlement of welding heat affected zone.

When vanadium, aluminum, titanium, niobium and other elements exist in steel, stable nitride can be formed with nitrogen, which improves the strength of steel and is beneficial to the performance of steel.

In the study of steel brittleness, it is found that manganese can decrease the brittleness sensitivity of steel, while chlorine increases it. The order of increasing embrittlement sensitivity of steel smelted by different methods is: open-hearth steel seperated with silicon and aluminum, open-hearth steel seperated with aluminum and semi-seperated steel, boiling steel or semi-seperated steel with oxygen blowing. This demonstrates the importance of free nitrogen in steel.

The nitrogen content of LD converter steel is 0.003%~0.006%. The nitrogen content of eAF steel is 0.008%~0.0016%. The highest solubility of nitrogen in A-Fe is about 0.1% at 590℃ and falls below 0.001% at room temperature. When steels with high free nitrogen content are cooled rapidly from high temperatures, ferrite will become saturated. If the steel is standing at room temperature, ammonia will be precipitated in the form of Fe4N with the increase of time, so that the strength and hardness of steel increase, plasticity and toughness decrease, that is, aging occurs.

To reduce the brittle transition temperature of steel, the content of nitrogen and silicon in steel should be reduced. Grain refiners (Al, V, Ti) with stable nitride elements should be used, especially in non-grain refined steels, and the total ammonia content should be the lowest. The helium content in grain refined steel should be the largest in order to fully form nitride and reduce the free nitrogen content.

For high carbon steel, vanadium is an element that can refine and disperse strengthen steel grains. When the free nitrogen content is 0.008%, the brittle transition temperature (FATT) is -5℃ by controlled rolling. The content of free nitrogen was 0.002% and the brittle transition temperature was -45℃.

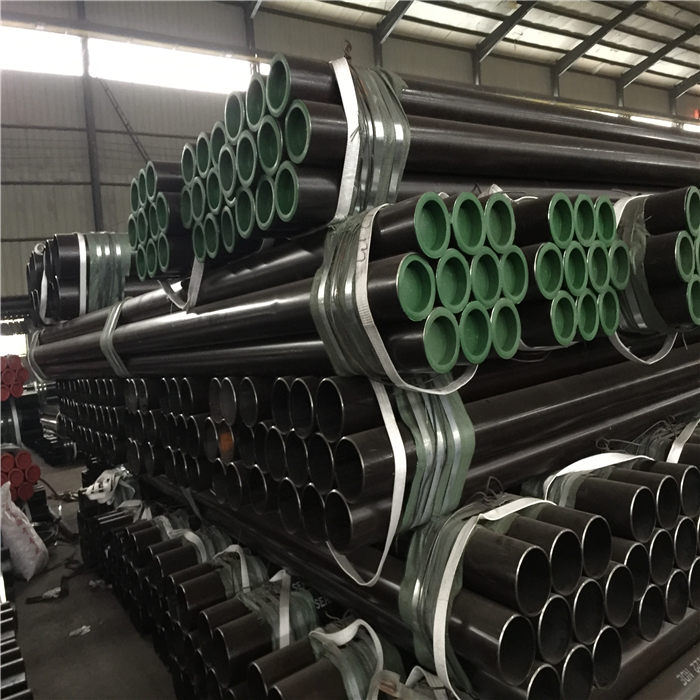

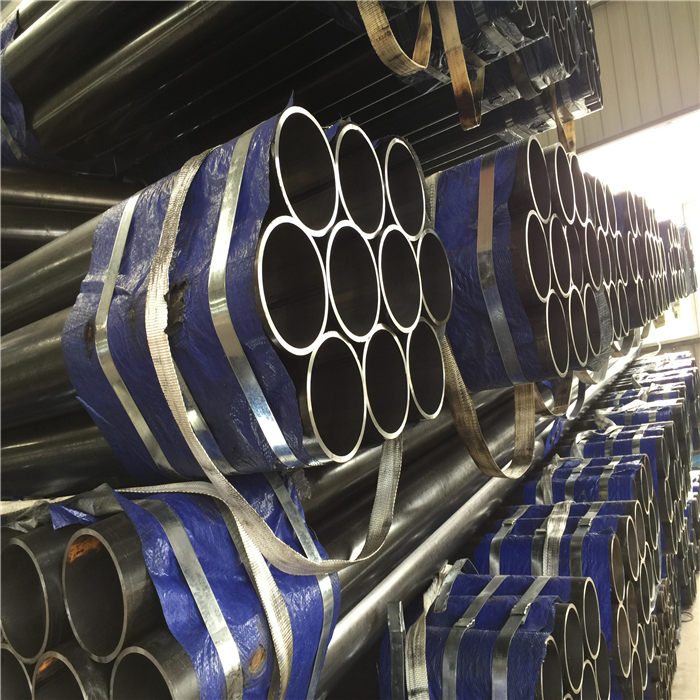

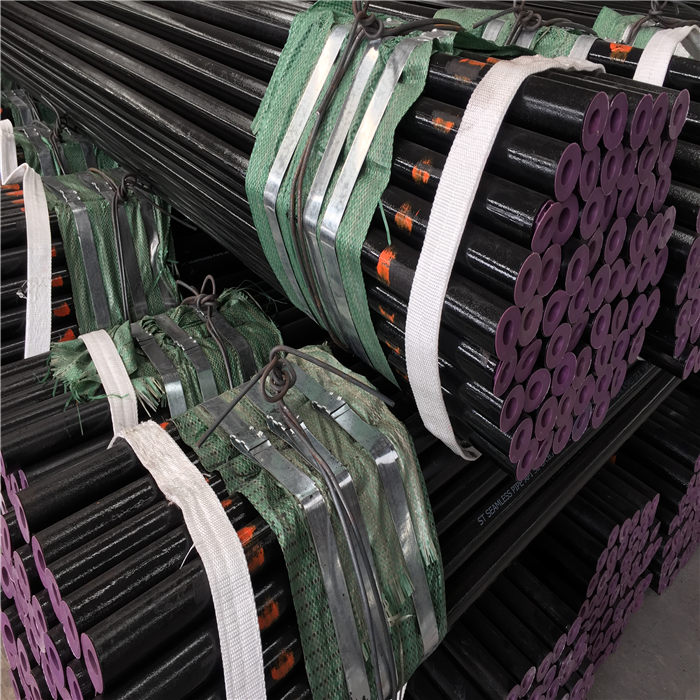

Galaxy Company Hot Sale Seamless Steel Pipe Products:

seamless steel pipe, line pipe, ASTM A106 pipe, , Mechanical pipe, API 5L pipe, boiler tube,ASTM A335 alloy pipes,GB/T5310 boiler Tub