Relationship Between Material Properties And Temperature

There are two types of material coefficient related to temperature: one is the material coefficient related to mechanical properties of materials; The other is the material coefficient related to heat conduction. Of the former are E, G, V, a; Belonging to the latter C(specific heat capacity), ρ (density), K (heat conduction coefficient) and so on. These coefficients are not actually constant, but vary with temperature. However, when the temperature is not high, the average value is usually taken as a constant. However, when the temperature is high and varies greatly, the change with the temperature must be considered.

1 The relationship between elastic coefficient and temperature.

The elastic coefficient E and shear modulus G of metal decrease with increasing temperature, while poisson's ratio V changes little with increasing temperature. E, G and temperature are determined by static method and dynamic method. The former is tested by loading in high temperature furnace, and the latter is determined by vibration method or ultrasonic pulse method. Vibration method is to make the specimen do elastic vibration in a high temperature furnace, and determine the elastic constant by measuring the frequency. The ultrasonic law is to measure E, G and V by measuring the propagation speed of the wave by applying ultrasonic waves to the specimen.

2. The relation of thermal coefficient to temperature

The thermal coefficient of metal materials has a linear relationship with temperature, linear expansion coefficient A increases linearly with the increase of temperature, thermal conductivity coefficient K decreases with the increase of temperature, and specific heat capacity increases with the increase of temperature. The variation of the thermal coefficient of a specific material with temperature can be known by measuring the slope of a straight line or the curvature of a curve of the relationship between the thermal coefficient and temperature. For example, the thermal coefficient of carbon steel varies with temperature from different sources as shown in Figure 1.

3 Thermal fatigue of materials

When the ductility material increases with temperature, even if the stress exceeds the yield point will not immediately damage, but even if the stress level is low, if there is a large temperature change repeatedly, eventually due to fatigue cracking and resulting in failure. This phenomenon is called thermal fatigue.

The strength of thermal fatigue refers to the relationship between the plastic strain P of a cycle and the number of failures N. According to manson-Coffin's empirical formula:

Material properties in relation to temperature - Iron and Steel Encyclopedia

Where, εf represents the elongation of the material when it is damaged in the static tensile test at the average temperature of a thermal cycle.

The above mentioned is only unidirectional thermal stress fatigue of materials, while the thermal fatigue of actual structures is multidirectional and is a special research field.

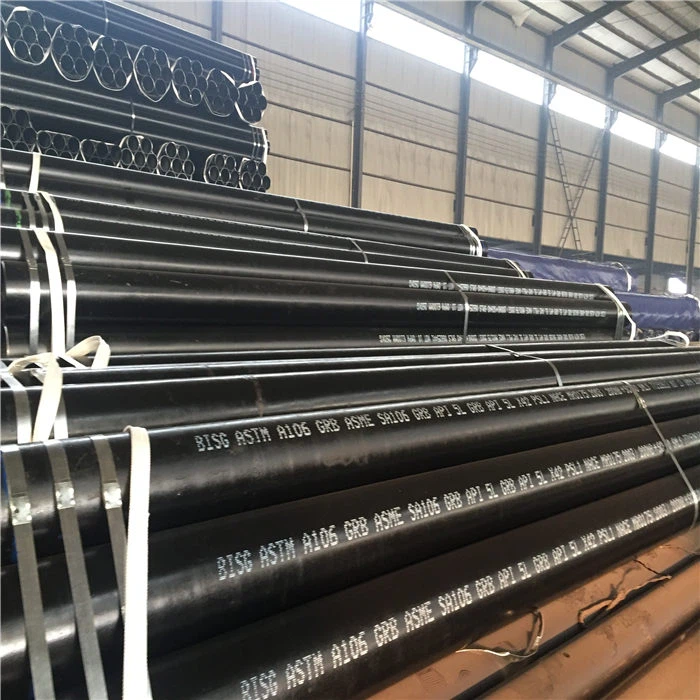

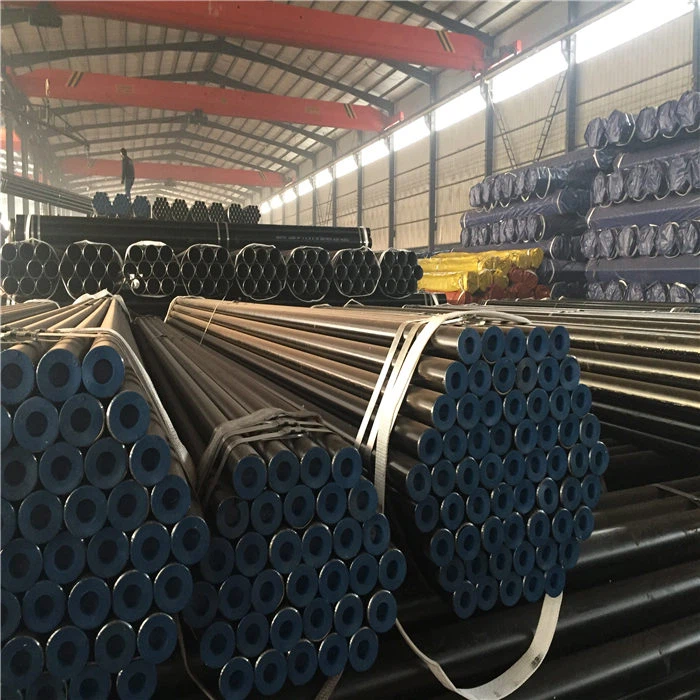

My company hot sale steel pipe:

ASTM A106 B seamless pipes,(1” to 24” sch40, sch80),

API 5L GR.B steel pipes, (seamless pipe, LSAW pipe, SSAW pipes, 1” to 110” sch 40, sch80),

Boiler tubes,( 20G. 12Cr1MoVG, ASTM A335 P5, P9, P11),

ASTM A333 GR.6 seamless pipes, ( 1” to 24” sch40, sch80, sch160)