Corrosion of metal materials for chemical pipelines

The harm of metal pipeline corrosion is very common and very serious. Corrosion will cause significant direct or indirect losses, will cause catastrophic major accidents, and endanger personal safety. The running, bubbling, dripping and leaking of production equipment and pipelines caused by corrosion will affect the production cycle and equipment life of the production unit, increase the production cost, and pollute the environment and endanger human health due to the leakage of toxic substances.

According to the mechanism of corrosion, it can be divided into chemical corrosion, electrochemical corrosion and physical corrosion.

1. Chemical Corrosion

Chemical corrosion refers to the damage caused by direct pure chemical interaction between the metal surface of the steel pipe and non-electrolyte. The sulfur corrosion of steel pipe metal in high temperature gas and the high temperature oxidation of seamless steel pipe metal belong to chemical corrosion.

2. Electrochemical Corrosion

Electrochemical corrosion refers to the damage caused by the electrochemical reaction between the metal surface of seamless steel pipe and the ionic conductive medium. Electrochemical corrosion is the most common and most common corrosion, such as the corrosion of seamless steel pipes in the atmosphere, seawater, soil and various electrolyte solutions.

3. Physical Corrosion

Physical corrosion refers to the destruction of steel pipe metal caused by simple physical dissolution. Its characteristics are: when the low melting point of the steel pipe metal is dissolved into the metal material, it will have a "cutting" effect on the metal material. Because the strength of metal with low melting point is generally low, it will preferentially break under the stress state, thus becoming the crack source of steel pipe metal materials. It should be said that such corrosion is rare in engineering.

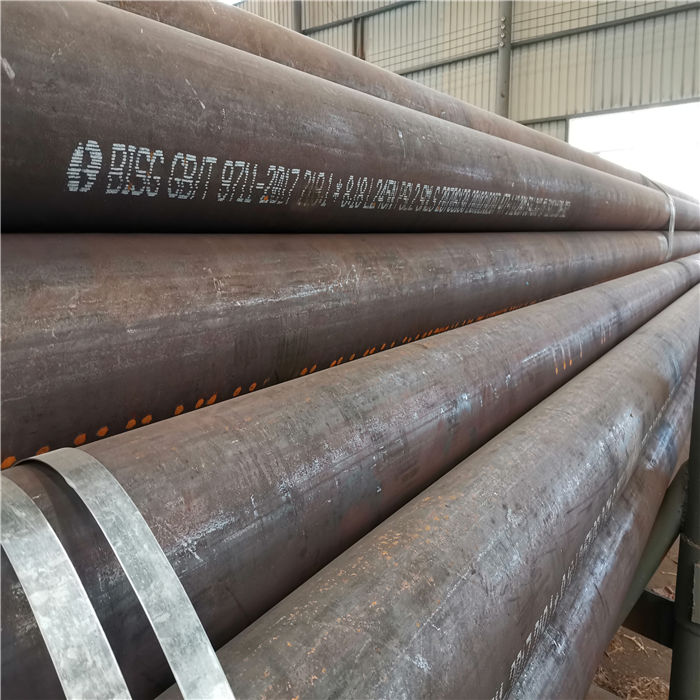

My company hot sale seamless steel pipes:

ASTM A106 B seamless pipes,(1” to 24” sch40, sch80),

API 5L GR.B steel pipes, (seamless pipe, 1” to 30” sch 40, sch80),

Boiler tubes,( 20G. 12Cr1MoVG, ASTM A335 P5, P9, P11),

ASTM A333 GR.6 seamless pipes, ( 1” to 24” sch40, sch80, sch160),