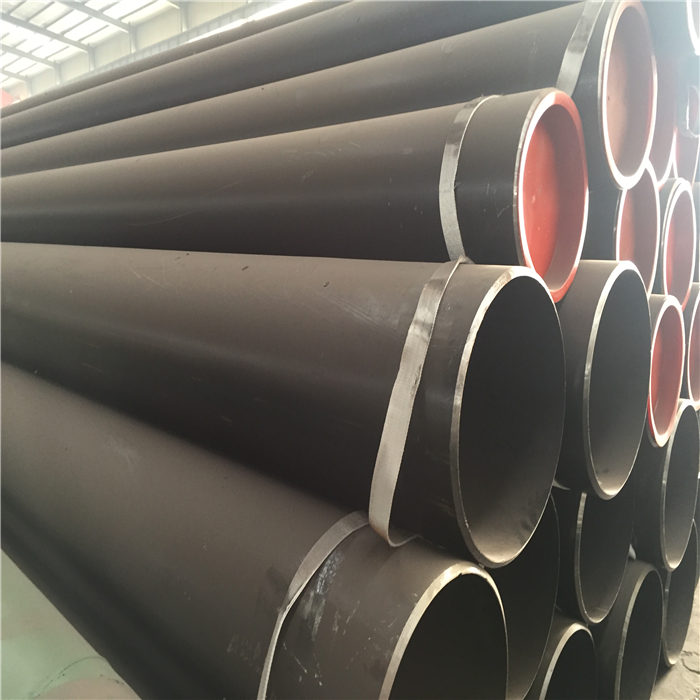

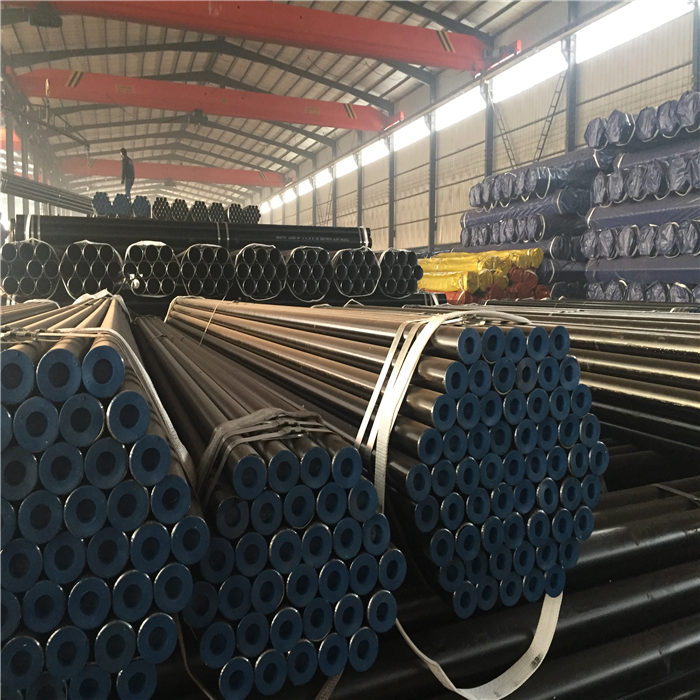

ASTM A 106 Seamless carbon steel Pipe

Seamless carbon steel Pipe is made by hot rolling and piercing a solid billet through it to leave a hollow tube. The pipe is then shaped to size and heat treated to specification. Seamless pipe is very common and considered a higher grade pipe. Applications include high pressure vessels, nozzles and critical applications requiring highest material integrity. Seamless pipe is also pressure tested to ASTM / ASME specification. Grade "B" signifies "seamless". A106 B seamless pipe is easily weldable using various welding procedures. This makes it preferred choice for pressure piping associated with various Oil, Gas and Industrial application. Seamless pipe is also very common in petrochemical industries for carrying high pressure fluid. Trupply offers seamless pipe for convenient online shopping in various lengths. 22 ft pipe is considered SRL "single random length" and actual length can vary from 19' to 22'.

Materials:

ASTM / ASME 106 B. It is considered dual certified (A106B and SA106B)

Size & Dimensions:

Seamless pipe is availabe from 1/8 to 40" NPS.

ASTM A106 and ASME SA106 seamless pressure pipe is commonly used in the construction of oil and gas refineries, power plants, petrochemical plants, boilers, and ships where the piping must transport fluids and gases that exhibit higher temperatures and pressure levels.

American Piping Products stocks a full range of A/SA106 pipe in:

- Grades B and C

- NPS ¼” to 40” OD

- Schedules 20 through XXH

- Wall Thickness up to 5.500″ Thick

- Scope

ASTM A106 and ASME SA106 covers seamless carbon steel nominal wall pipe for high-temperature service. Suitable for bending, flanging and similar forming operations.

NPS 1-1/2″ and under may be either hot finished or cold drawn. NPS 2″ and larger shall be hot finished unless otherwise specified.

Process

Killed steel, with primary melting process being open-hearth, basic-oxygen, or electric-furnace, possibly combined with separate degassing or refining.

Steel cast in ingots or strand cast is permissible.

Hot-finished pipe need not be heat treated.

Cold-drawn pipe shall be heat treated after the final cold draw pass.

Chemical Requirements

| Grade A | Grade B | Grade C | |

| Carbon max. % | 0.25 | 0.30* | 0.35* |

| *Manganese % | 0.27 to 0.93 | *0.29 to 1.06 | *0.29 to 1.06 |

| Phosphorous, max. % | 0.035 | 0.035 | 0.035 |

| Sulfur, max. % | 0.035 | 0.035 | 0.035 |

| Silicon, min.% | 0.10 | 0.10 | 0.10 |

| Chrome, max. % | 0.40 | 0.40 | 0.40 |

| Copper, max. % | 0.40 | 0.40 | 0.40 |

| Molybdenum, max. % | 0.15 | 0.15 | 0.15 |

| Nickel, max. % | 0.40 | 0.40 | 0.40 |

| Vanadium, max.% | 0.08 | 0.08 | 0.08 |

| Unless otherwise specified by the purchaser, for each reduction of 0.01% below the specified carbon maximum, an increase of 0.06% manganese above the specified maximum will be permitted up to a maximum of 1.65% (1.35% for ASME SA106). | |||

Total of Cr, Cu, Mo, Ni, and V shall not exceed 1%

Tensile Requirements

| Seamless | |||

| Grade A | Grade B | Grade C | |

| Tensile Strength, min., psi | 48,000 | 60,000 | 70,000 |

| Yield Strength, min., psi | 30,000 | 35,000 | 40,000 |

Hydrostatic Testing

Inspection test pressures produce a stress in the pipe wall equal to 60% of specified minimum yield strength (SMYS) at room temperature. Maximum Pressures are not to exceed 2500 psi for NPS3 and must stay under 2800 psi for the larger sizes. Pressure is maintained for not less than 5 seconds.

Lengths

Lengths required shall be specified on order. No “jointers” permitted unless otherwise specified. If no definite lengths required, following practice applies: Single Random — 17′ ~ 24′ lengths Double Random — 36′ ~ 44′ lengths

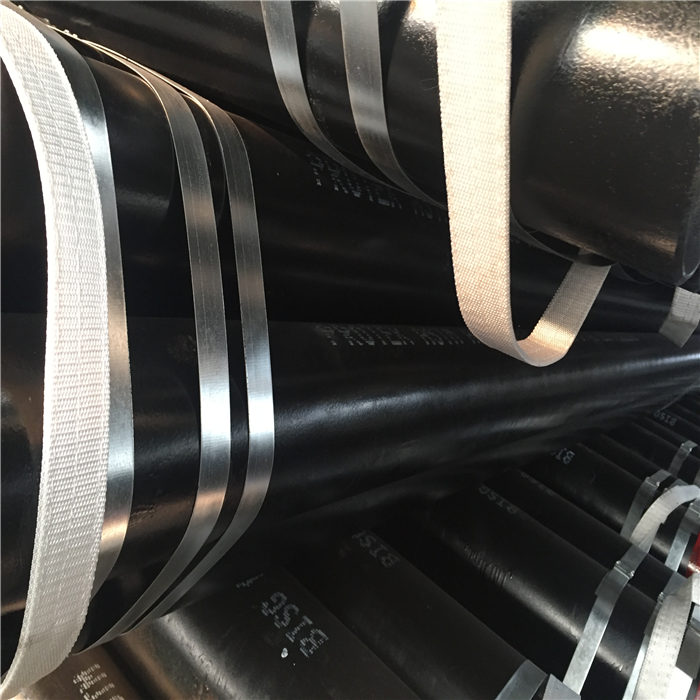

Required Markings on Each Length

(On Tags attached to each Bundle in case of Bundled Pipe) Rolled, Stamped, or Stenciled (Mfrs. Option) Manufacturer’s name or brand. Length of pipe. A106 A, A 106 B, A 106 C. ANSI schedule number. Hydrostatic test pressures and/or NDE; Weight per foot (NPS 4 and larger) or NH if neither is specified. Additional “S” if tested supplementary requirements.

Referenced Documents

- ASTM A 530/A 530M Specification for General Requirements for Specialized Carbon and Alloy Steel Pipe

- ASTM E 213 Practice for Ultrasonic Examination of Metal Pipe and Tubing

- ASTM E 309 Practice for Eddy-Current Examination of Steel Tubular Products Using Magnetic Saturation

- ASTM E 381 Method of Macroetch testing Steel Bars, Billets, Blooms, and Forgings

- ASTM E 570 Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products

- ASME B36.10M Welded and Seamless Wrought Steel Pipe

General Information

Orders for material under this specification should include the following, as required, to describe the desired material adequately:

| Quantity | Feet, centimeters, or number of lengths | ||||

| Name of material | Seamless | ||||

| Grade | Grade A, Grade B, or Grade C | ||||

| Manufacture | Hot-finished or cold-drawn | ||||

| Size | NPS or Outside Diameter and Schedule Number of Average Wall Thickness | ||||

| Special outside diameter tolerance pipe | |||||

| Inside diameter tolerance pipe, over 10 in ID | |||||

| Length | Specific or random | ||||

| Supplementary requirements | |||||

| Test Report Required | |||||

| Specification designation | |||||

| Hydrostatic test | |||||

| Special requirements | |||||

ASTM A 106 grade B Seamless Pressure Pipe

B) Unless otherwise specified by the purchaser, for each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % manganese above the specified maximum will be permitted up to a maximum of 1.65 %.

ASME SA 106 grade B Seamless Pressure Pipe

B) For each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % manganese above the specified maximum will be permitted up to a maximum of 1.35 %.