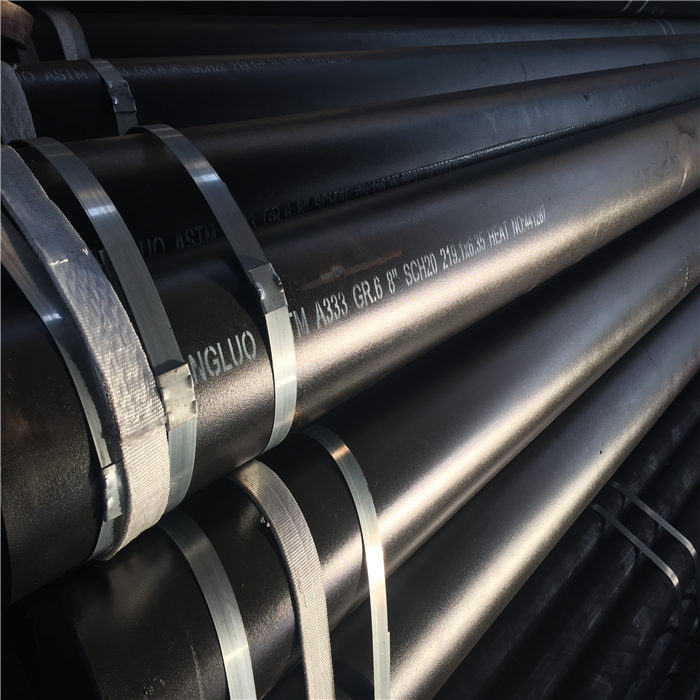

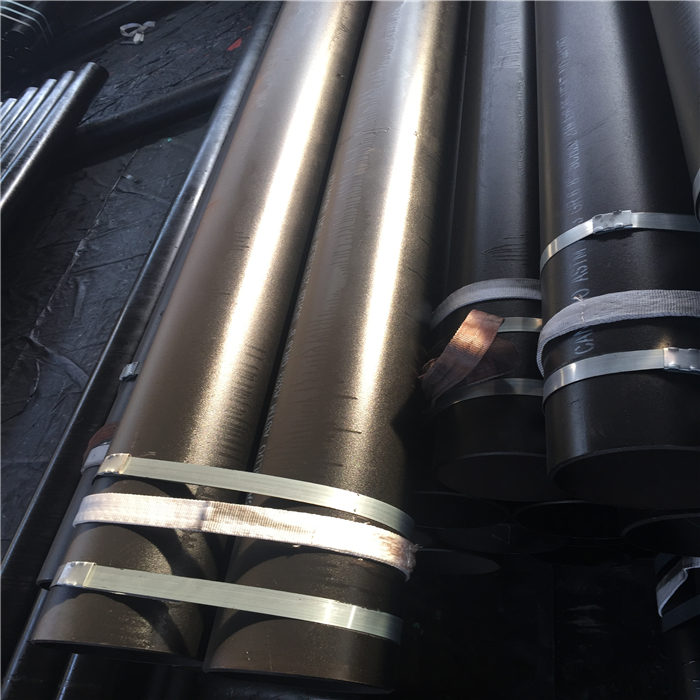

API 5L Seamless Line Pipe

API 5L is a relatively comprehensive specification,mainly developing line pipes for the oil and gas industry;the range of strength levels is much wider.While the lower strength grades A & B are comparable to ASTM A106,the strength of other grades are much higher (e.g. X42, X56, X60, etc.).In addition,the quality rating is more stringent when API 5L line pipe PSL2 is applied,the rolling rating is not acceptable and rework is not allowed.Moreover, particular attention is given to toughness and toughness tests for sour services and higher pressure/ temperature classes.

- Specification: API 5L

- Size Range: 2" - 26"

- Schedules: STD, XH, 40, 80, 100, 120, 160, XXH

- Additional Services: Fusion Bond Epoxy, ARO, 3LPE, Tar Epoxy

- End Types: Beveled ends, plain ends

Seamless Carbon Steel Pipe API 5L

|

High Yield Carbon Steel |

API 5L Seamless – Grades B, X42, X52, X60, X65, X70 |

API 5L Seamless Steel Pipe Chemical Composition & Grades

|

API 5L Grades |

API 5L Chemical Composition |

|||||||

|

|

C |

Si |

Mn |

P |

S |

V |

Nb |

Ti |

| API 5L X42 |

0.16 |

0.45 |

1.65 |

0.020 |

0.010 |

0.07 |

0.05 |

0.04 |

| API 5L X52 |

0.16 |

0.45 |

1.65 |

0.020 |

0.010 |

0.07 |

0.05 |

0.04 |

| API 5L X60 |

0.16 |

0.45 |

1.65 |

0.020 |

0.010 |

0.08 |

0.05 |

0.04 |

| API 5L X65 |

0.16 |

0.45 |

1.65 |

0.020 |

0.010 |

0.09 |

0.05 |

0.06 |

| API 5L X70 |

0.17 |

0.45 |

1.75 |

0.020 |

0.010 |

0.10 |

0.05 |

0.06 |

API 5L Seamless Steel Pipe Yield & Tensile Strength

|

API 5L Grades Grade |

Yield Strength |

Tensile Strength |

Yield to Tensile |

Elongation |

|

|

min. (KSI) |

min. (KSI) |

Ratio (max) |

% |

| API 5L X42 |

42 |

60 |

0.93 |

23 |

| API 5L X52 |

52 |

66 |

0.93 |

21 |

| API 5L X60 |

60 |

75 |

0.93 |

23 |

| API 5L X65 |

65 |

77 |

0.93 |

18 |

| API 5L X70 |

70 |

82 |

0.93 |

17 |

Industries Served

We can help supply all of the High Yield Seamless API 5L steel pipe or line pipe supplies that your company needs for use in a wide range of industries. Some of the common industries we serve include:

- Oil & Gas

- Natural Gas

- Petroleum

- Water

- Automobile

- Infrastructure

- Fabrication

- Construction

- Chemical

Common Applications of the High Yield Carbon Steel Pipe

Worldwide Pipe & Supplys high yield carbon steel pipe is commonly known for transporting water, oil, and gas. API 5L Line Pipe Specifications for these pipes regulate usage for standard Grade A and Grade B pipes, with Grade X indicating stronger variants for drilling, production, and transport requirements for offshore, arctic, deep well, or harsher environments.

Value-Added Services

Worldwide Pipe offers a range of value-added services such as threading, fabricating, coating, and logistics to help tailor products to your unique project specifications. Some of the common services we provide for our high yield carbon steel pipe includes:

- Fusion Bond Epoxy (FBE)

- Abrasion Resistant Overlay (ARO)

- 3LPE Coating

- Tar Epoxy

The abrasion-resistant overlay is applied to the pipes to provide a layer of protection and provide corrosion control. Fusion Bond Epoxy, or FBE systems, are applied to pipes to enhance the flow characteristics of gas or oil flowing through a pipe or pipeline system. 3LPE coating is a 3-layer coating that is applied to pipes in order to prevent chemical and corrosion damage. Layer 1 consists of FBE, layer 2 is a copolymer adhesive, and layer 3 is made up of a layer of polyethylene. The tar epoxy coating service is applied to pipes to protect against severe abrasion.