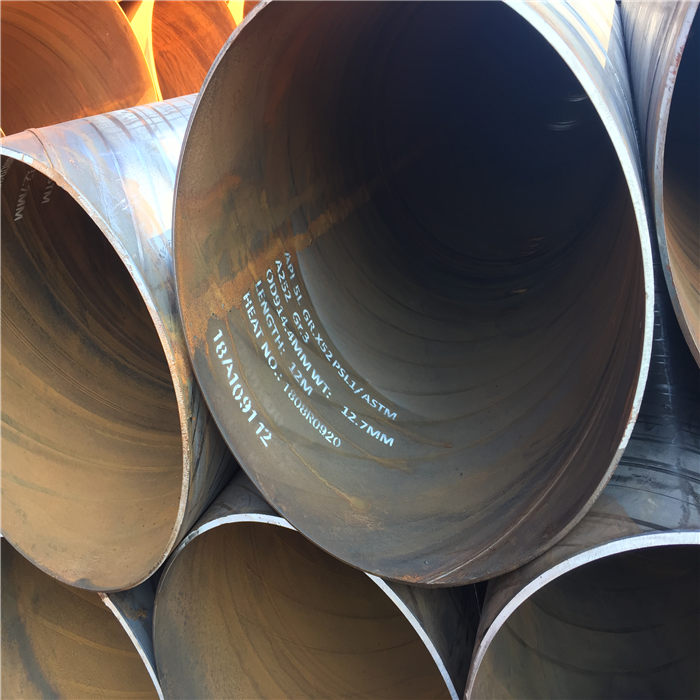

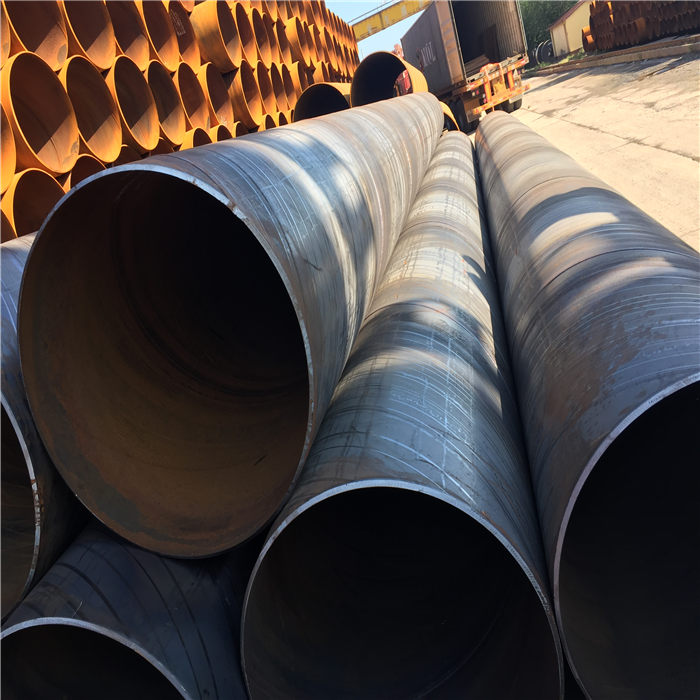

Spiral Submerged Arc Welded Steel Pipe

SSAW steel pipe (spiral submerged arc welded steel pipe, spiral seam steel pipe, spiral welded pipe, spiral pipe, spiral steel pipe ) is formed by spiral bending of hot-rolled steel strip, and automatic welding of submerged arc for inner and outer joints. welding line shape like a helix. SSAW Pipes use the same submerged arc welding technology with LSAW pipe. Differently, SSAW pipes are spiral welded whereas the LSAW pipes are longitudinally welded. The manufacturing process is rolling the steel strip, to make the rolling direction have an angle with the direction of the pipe center, forming and welding, so the welding seam is in a spiral line.

For larger dimension pipes, we should recommend spiral submerge arc welding pipes. With this kind of pipes, The diameter can reach to 4m.

We can use narrow width steel plates to produce large dimension pipes.The outside diameter is determined by the angle of the de-coiled steel against the forming head. In this welding process, the material is submerged under a bed of fusible flex, which becomes conductive when heated. The resulting weld is sound, uniform and corrosion resistant, with a deep weld penetration. It is a high-speed production,

Standard of SSAW Steel Pipe:

GB/T 14291,GB/T 3091,GB/T 9711.1,GB/T 9711.2

SY/T 5037,SY/T 5040

ASTM A53, ASTM A252

BS EN10217-2,BS EN10217-5,BS EN10219-1,BS EN10219-2

API 5L PSL1/2, ISO 11960 PSL1

Applications of SSAW Pipes

-

For fluid sevice

-

For low pressure fluid service

-

For pipelines for low pressure fluid service

-

For pressure purposes

-

For pipe piles

-

For pipeline transportation system of petroleum and natural gas industries

-

Water and other flammable & nonflammable liquid conveyance and distribution pipelines

-

Steel structures for construction