What are the different types between Line Pipe and OCTG pipe?

Within the oil and gas industry, two essential steel pipe components play distinct roles in facilitating the extraction, transportation, and distribution of hydrocarbons: line pipe and OCTG (Oil Country Tubular Goods). While both are critical, understanding their unique characteristics and applications is essential for ensuring efficient operations in the industry.

Line Pipe: Line pipe refers to a type of steel pipe specifically designed for the transportation of fluids, primarily oil and natural gas, over long distances. These pipes are manufactured to withstand high pressures, corrosive environments, and variable temperatures. Line pipes are typically laid out in extensive networks of pipelines, forming the backbone of the oil and gas transportation infrastructure.

Line pipe is very strong carbon steel pipes which are used for the transportation of various petroleum products, natural gas, oil and water. API 5L is a specification of American Petroleum Institute which regulates and defines the standard for the dimension, physical, mechanical and chemical properties of the steel used for the manufacturing of line pipe. Numerous pipe manufacturing companies across the globe follow the API 5L guidelines for the OCTG line pipe used in the Oil and Gas industry. line pipe is available in a wide range of diameter sizes ranging from 2 inches to 48 inches.

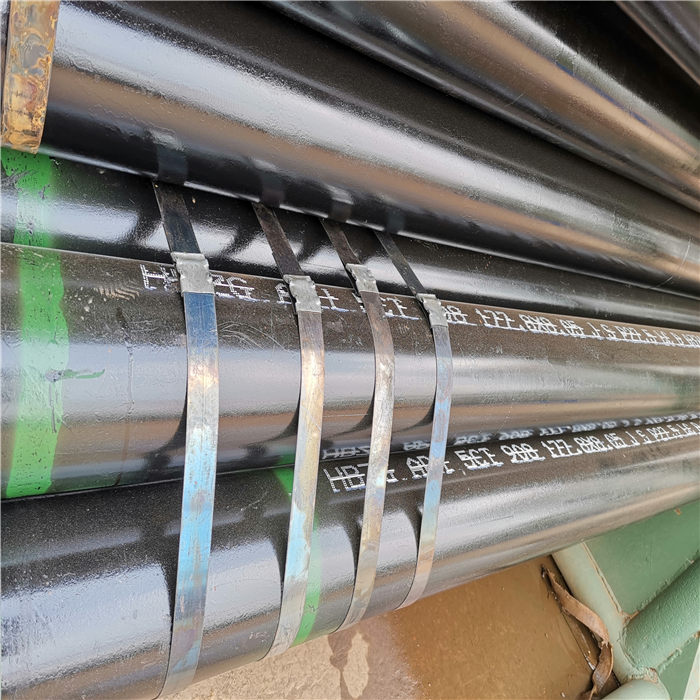

Line pipes are manufactured with high-strength steel to withstand the demanding conditions of pipeline transportation. They undergo stringent quality control processes and are manufactured in various sizes, wall thicknesses, and grades to meet specific project requirements.

Line pipes are designed to withstand external forces, such as soil movement, external corrosion, and temperature variations. Coatings and corrosion protection measures are employed to ensure their longevity and operational integrity in diverse environments.

Line pipes are primarily used for the transportation of oil, gas, and other fluids from production sites to refineries, processing plants, and distribution points. They are designed to withstand high pressures, facilitate efficient flow, and ensure the safe and reliable delivery of hydrocarbons.

The term Oil Country Tubular Goods (OCTG) describes tubes that are used both onshore and offshore in oil and gas production or the upstream side of the industry. PipeSearch focuses on two main types of OCTG: casing and tubing. OCTG casing and tubing are key components in the completion and production of oil, gas, and injection wells.

OCTG (Oil Country Tubular Goods): OCTG refers to a broad category of steel tubular products used in the construction and maintenance of oil and gas wells. OCTG includes casing, tubing, and drill pipes, which are essential for drilling, completion, and production operations. These tubular goods provide structural support, facilitate fluid flow, and ensure well integrity in various stages of well development.

OCTG products are specifically designed for use in well construction, completion, and production operations. Casing pipes are used to line the wellbore, providing structural support and isolating different formations. The tubing allows for fluid injection and production, while drill pipes facilitate drilling operations.

OCTG products are also made from high-quality steel and are subject to rigorous testing and inspection. However, their specifications differ based on their intended application. Casing pipes are available in various diameters, weights, and grades, depending on the well’s depth, formation characteristics, and environmental factors. Tubing and drill pipes have specific dimensions and features suited for their respective functions.

OCTG products are subject to internal and external pressures, corrosive fluids, and extreme temperatures within the wellbore. Specialized coatings, such as corrosion-resistant alloys, are applied to protect against internal and external corrosion and erosion caused by fluid flow and downhole conditions.

Casing:

Casing pipe is used for lining the borehole which has been dug into the ground for procuring oil or gas and stabilizing it. A casing pipe is subject to axial tensions and high internal pressures which are generated while pumping oil or gas. They also have to bear the external pressures arising from the surrounding rocks underground.

OCTG casing is large diameter pipe which needs to be cemented into the borehole. The diameters of OCTG casing pipe range from 4.5″ to 20″. The pipe is well-cemented and stands strong, it acts as the structural component of the well and offers hole integrity. The casing prevents the well from collapsing when the drilling process is on. Well cemented casing should last the life of the well.

Casing is required during the drilling process as it is necessary for the following:

Tubing:

Tubing pipe is pipe which is placed inside the wellbore through the casing pipe. It is responsible for the transportation of the hydrocarbons to the surface. Tubing pipe is used for transporting natural gas or crude oil after the drilling is complete. It transports the gas and oil to the facilities for further processing. Similar to the drill pipe and casing, tubing pipe also has to withstand high pressure during the extraction process, and hence they are required to meet industry standards. Tubing pipe are available in various sizes ranging from 1 1/4” to 4.5”.

Tubing protects the casing from wear and tear caused by corrosive fluids, sand, paraffin, and more. In case of damage or breakage, tubing pipe can be easily replaced.

Drill pipe:

Drill pipe is hardwearing seamless pipe which are rotated in order to circulate the drilling fluid. This pipe is useful for pumping back the drilling fluid back up the annulus. The annulus is the space in the oil well between the casing and the piping. Easy circulation of the fluid within the well is possible because of the Annulus. The drill pipe is subject to axial tension since high torque is required for rotating the down-hole assembly and drilling the fluid and circulating it. The OCTG drill pipe needs to be extremely strong as they have to bear a high amount of stress underground. The drill pipe is used at the drilling rigs and they are available in different sizes and different qualities. OCTG drill pipe needs to be sturdy and meet the standards of API 5DP and API SPEC 7-1.