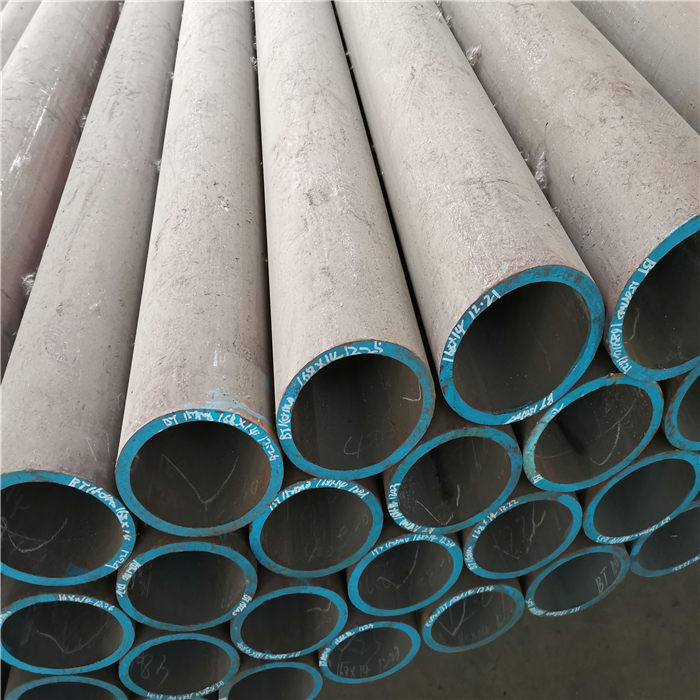

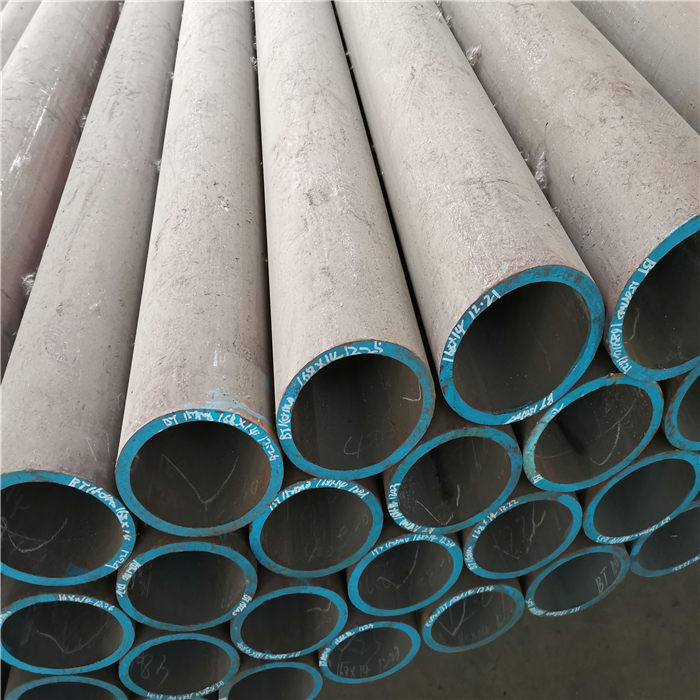

20G seamless boiler steel pipe 1 to 20" size

20G seamless boiler pipes supplied according to GB5310 standard is applicable to seamless tubes for making steam boiler and superheater 20G, 20MnG, 25MnG, 15CrMoG, 12Cr2MoG, 12Cr1MoVG, 10Cr9Mo1VNbN

Product Introduction

GB 5310- 2008 standard is applicable to seamless tubes for making steam boiler whose pressure is high or higher and seamless tubes used as pipelines.

20G seamless steel pipe is a high-quality carbon steel, boiler material, the carbon content of 0.17-0.24%, tensile strength of 410Mpa, yield point 230-250Mpa.

Grade 20G Seamless Steel Boiler tube is applicable to seamless tubes for making steam boiler whose pressure is high or higher and seamless tubes used as pipelines.

The versatile nature of 20G seamless steel pipes makes them suitable for a range of industrial applications:

-

Boilers: In the power generation sector, 20G pipes are used as superheater tubes, reheater tubes, and waterwall tubes in boilers, facilitating the exchange of heat and steam generation.

-

Heat Exchangers: These pipes play a crucial role in heat exchangers, where they enable efficient transfer of thermal energy between fluids in different industrial processes.

-

Petroleum Industry: The pipes find application in petroleum refineries for transporting high-temperature and high-pressure fluids.

Considerations for Usage

When incorporating 20G seamless steel pipes into industrial systems, the following factors should be considered:

-

Operating Conditions: Ensure that the pipes are suitable for the specific temperature, pressure, and fluid characteristics of the application.

-

Compatibility: Verify compatibility with other components and materials within the system to prevent potential issues.

Chemical Compositions(%) of GB5310 20G:

| Chemical elements | Data |

| Carbon | 0.17-0.24 |

| Silicon | 0.17-0.37 |

| Manganese | 0.70-1.00 |

| Phosphorus(max) | 0.03 |

| Sulfur(max) | 0.03 |

| Chromium(max) | 0.25 |

| Molybdenum(max) | 0.15 |

| Cuprum(max) | 0.2 |

| Nickel(max) | 0.25 |

| Vanadium(max) | 0.08 |

Mechanical Properties of GB5310 20G:

| Properties | Data |

| Yield Strength (Mpa) | ≥415 |

| Tensile Strength (Mpa) | 240 |

| Elongation (%) | 22 |

The W.T. tolerance of GB5310 20G:

| W.T.(S) | Tolerance of W.T. | |

| <3.5 | +15%(+0.48mm min) | |

| -10%(+0.32mm min) | ||

| 3.5-20 | +15%,-10% | |

| >20 | D<219 | ±10% |

| D≥219 | +12.5%,-10% | |

Additional Condition

UT(Ultrasonic examination), AR(As Hot Rolled only), TMCP(Thermal Mechanical Control Processing), N(Normalized), Q+T(Quenched and Tempered),Z Direction Test(Z15,Z25,Z35), Charpy V-Notch Impact Test, The Third Party Test (such as SGS Test), Coated or Shot Blasting and Painting.

we can provide 20G Seamless pipe with high quality and competitive price.

My company hot sale steel pipe and pipe fittings:

ASTM A106 B seamless pipes,(1” to 24” sch40, sch80),

API 5L GR.B steel pipes, (seamless pipe, LSAW pipe, SSAW pipes, 1” to 110” sch 40, sch80),

Boiler tubes,( 20G. 12Cr1MoVG, ASTM A335 P5, P9, P11),

ASTM A333 GR.6 seamless pipes, ( 1” to 24” sch40, sch80, sch160),

TP304/304L, TP316/TP316L, stainless steel pipes, (1” to 48” sch10, sch20, sch40, sch80),

API 5L X65, X70 PSL2 LSAW welded pipes, (20” to 60” sch40, sch80, sch160),

API 5CT seamless casing, and tubing, (2 3/8” to 20” K55, J55, N80, L80, P110),

Pipe fittings, elbow, reducer, ,tee,cap, flange

You Might Also Like

-

large diameter Seamless Line Pipes API 5L GR.B 1016x25.4 mm 6 m length

-

St37 Seamless Tube 88.9mm Diameter

-

Seamless Steel Pipe ASTM A106 B NACE MR 0175 12IN SCH160

-

Seamless Line Pipe API 5L GR.B 24INCH SCH40 12M Length

-

Seamless Pipe 2inch Idimeter XXS 6 M LENGTH Export

-

Seamless Pipe ASTM A106 C 10IN Diameter XS 12M Length

Send Inquiry