Classification Of Steel Pipes

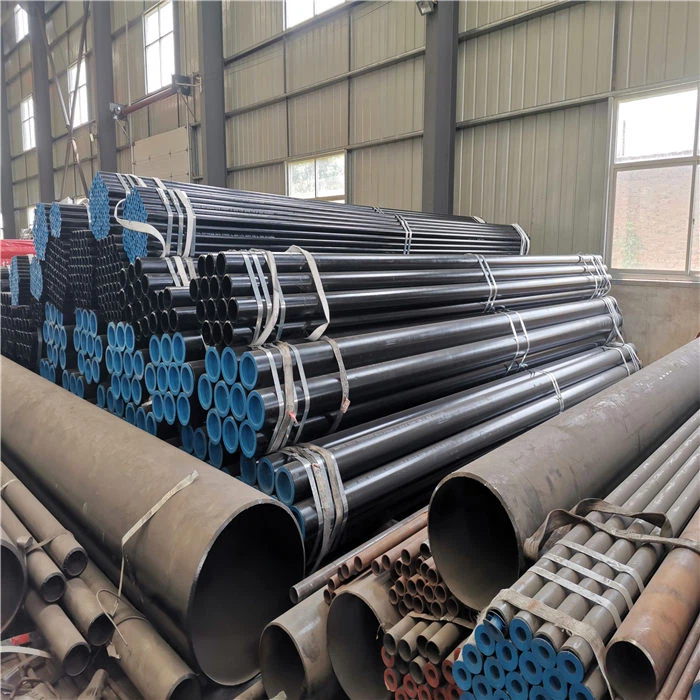

All the two ends of the opening and hollow section, and its length and section circumference of the larger comparison of steel, can be called steel pipe.

Steel pipe is a kind of economic steel, is an important product in the steel industry, usually accounting for about 10% of the total amount of steel, it is widely used in the national economy. Because of the hollow section of the steel pipe, it is the most suitable for fluid conveying pipeline. At the same time, compared with the same weight of round steel, steel pipe section flexural torsional strength coefficient is big, big, and become the important materials, all kinds of machinery and building structure, especially in the oil drilling, smelting and transportation needs most, the second address drilling, chemical industry, building industry, mechanical industry, aircraft and automobile manufacturing, medical equipment, furniture, and boiler and bicycle, etc., They all need a lot of steel pipes. In recent years, with the development of new technologies such as atomic energy, rocket, missile and aerospace industry, the status of steel pipe in national defense industry, science and technology and economic construction is more and more important, with the industrial "blood vessel". In terms of general use, the most pipes are pipes, followed by the structure.

1.1 Classification of steel pipes

There are many kinds of steel pipes, different uses, different technical requirements, production methods are also different. The current production of steel pipe diameter from 0.1 ~ 4500 mm, wall thickness of 0.01 ~ 250 mm. In order to distinguish its characteristics, steel pipes are usually classified as follows:

According to the production mode: steel pipe is divided into seamless pipe and welded pipe two categories, seamless steel pipe can be divided into hot rolled pipe, cold rolled pipe, cold drawn pipe and extrusion pipe; Cold drawing and cold rolling are the secondary processing of steel pipe. Welded pipe is divided into straight seam welded pipe and spiral welded pipe.

According to the cross-section shape of steel pipe: according to the cross-section shape can be divided into round pipe and special-shaped pipe; Special-shaped tube: rectangular tube, rhomboid tube, elliptical tube, six square tube, eight direction tube and a variety of cross section asymmetric tube; According to the longitudinal section shape can be divided into equal section pipe and variable section pipe; Variable section pipe has conical pipe, ladder pipe and periodic section pipe, etc.

According to the material of the steel pipe, the steel pipe is divided into ordinary carbon steel pipe, carbon structure steel pipe, alloy structure steel pipe, alloy steel pipe, bearing steel pipe, stainless steel pipe and bimetal composite pipe, coating and coating pipe to save precious metals and meet special requirements.

According to the shape of the pipe end: according to the state of the pipe end, it can be divided into light pipe and wire pipe (with rebar steel pipe). Turning wire pipe can be divided into ordinary turning wire pipe (water, gas and other low-pressure pipe, using ordinary cylindrical or conical pipe thread connection) and special thread pipe (oil, geological drilling pipe, using special thread connection, for important turning wire pipe), for some special pipe, in order to make up for the effect of thread on the pipe end strength, The pipe end is usually thickened (inside, outside or inside) before the wire is spun.

According to the ratio of outer diameter (D) to wall thickness (S) (D/S), the steel tubes are divided into extra-thick tubes (D/S≤10), thick-walled tubes (D/S = 10-20), thin-walled tubes (D/S = 20-40) and extremely thin-walled tubes (D/S≥40).

According to use: oil well pipe (casing, tubing and drill pipe, etc.), pipeline pipe, boiler pipe, mechanical structure pipe, hydraulic prop pipe, gas cylinder pipe, geological pipe, chemical pipe (high-pressure fertilizer pipe, petroleum cracking pipe), ship pipe, etc.